Foreign and domestic feeder data monitoring technology has the problem that there are few monitoring items and the monitoring data can not fully reflect the operation state of heavy plate feeder. The system consists of four modules: signal acquisition terminal, local workstation, information processing and analysis and central display control terminal. Through the understanding of the working principle of each sensor and the analysis of the use environment and performance, it can be found that many working units of heavy plate feeder are of great significance.

1. Frequency converter is the basis of the whole monitoring system

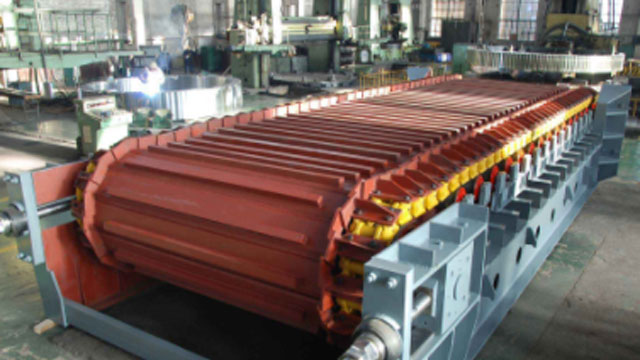

The plate feeder is a low-speed, heavy-duty and impact resistant large-scale material transportation equipment. It uses the frequency converter as the system foundation to build a monitoring network, installs a camera on the periphery of the equipment to check the operation status, measures the bearing temperature at four bearing points of the main shaft and tensioning shaft, monitors the power supply current and real-time motor power of the motor, and the accuracy of the collected information is rounded by the original reading, Up to now, the data acquisition and processing are completed through the frequency conversion control cabinet. When the temperature, current or power is abnormal, the frequency converter alarms and stops. The frequency conversion control cabinet provides data input and output ports, which are connected to the general control room of the factory. The general control room controls the operation of the equipment through digital information and analog information. The frequency domain of control and adjustment has also been greatly improved. Taking motor frequency modulation as an example, the frequency modulation amplitude can reach one thousandth of Hertz. During adjustment, the equipment will not have Caton feeling and realize stepless speed regulation. There is a spare parts storage near the plate feeder, which can be replaced directly in case of damage.

2. PLC monitoring can ensure the normal state of the equipment

The data processing and equipment control functions of the monitoring system are integrated into the frequency conversion control cabinet, and the measured physical elements are replaced with cold resistant or heat-resistant types according to the different use environment. According to the mature electronic and network technology, semi automation is basically realized in the data monitoring of the heavy plate feeder, which can query the equipment status from a long distance, start and stop the heavy plate feeder with medium and long-distance wireless remote control, design a multi-point measurement method, and measure the height of the material layer with ultrasonic wave ranging sensor. In order to reduce the influence of plate feeder reading into signal transmission in the workstation and reduce the interference in the long-distance feeder.

In the information processing and analysis module, eliminate the abnormal and random error information, analyze the change law of bearing temperature, set the normal temperature limit of three bearing temperature measurement areas, and set the normal display and alarm limit range of I-beam groove steel beam deformation and chain plate wear according to the stress analysis and wear comparison. The secondary measurement is used to determine the abnormal information, the limited principle is used to store the effective information, the indirect measurement information is calculated according to the formula, the dynamic curve of each information along the time axis is drawn respectively, and the historical information query is set up.